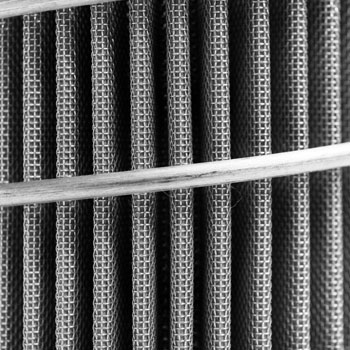

SS Powder Sintered filters are mainly used for filtration of harsh fluids and can be utilized in high temperature conditions as well. Special materials like Hastelloy X can be made use of to fabricate such filters. The sintered metal powder forms a porous structure that traps particles as small as 0.2 microns with exceptional efficiency. Sintered Powdered Filter Cartridges are renowned for their exceptional filtration efficiency and reusability. These SS filter cartridges are constructed from 316/316L grade stainless steel.