Stainless Mesh Filter Manufacturer | SS Wire Mesh filter

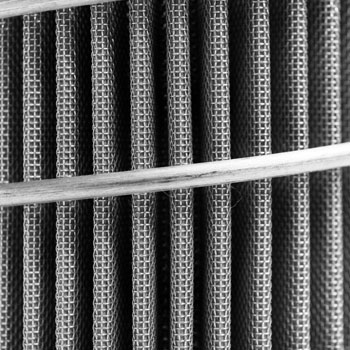

Stainless mesh filters (Pleated SS 316/304 mesh cartridges) offer the convenience of having a larger filtration area within a small enclosure since the media is pleated and enclosed within a cage of suitable diameter.

Experience superior filtration efficiency with our SS wire mesh filters (pleated), designed to withstand high temperatures, pressures, and cleaning methods for long-lasting performance.

Dust Filtration, Viscous Fluids filtration, high pressure & high temperature molten monomer / polymer filtration etc.